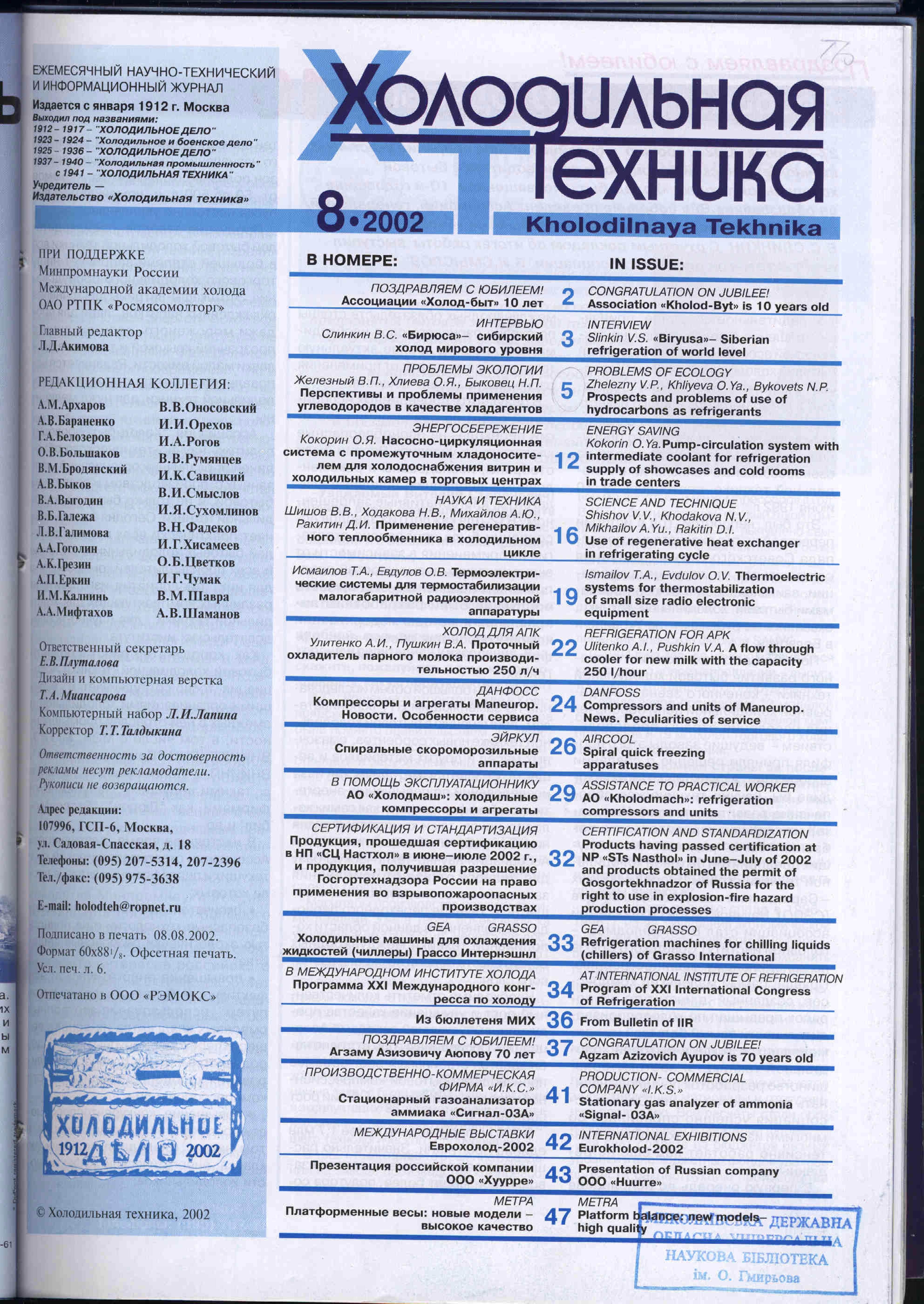

Vol 91, No 8 (2002)

Articles

Prospects and problems of application of hydrocarbons as refrigerants

Abstract

It is shown that scientifically based conclusion about the prospects for use of hydrocarbons in refrigeration equipment can be made only within the frame of modern methods of ecological, thermal and economical analysis. The main principle of ecological, thermal and economical analysis consists in taking account of the emissions of greenhouse gases during production and operation of refrigeration equipment, i.e. for the whole life cycle of the machine.

5-9

5-9

Pumping and circulating system with intermediate coolant for refrigeration supply of showcases and cold rooms in shopping centers

Abstract

A pump-circulation refrigeration system using ecologically safe antifreeze (propylene glycol) as if cooling medium is described. A peculiar feature of the system is that in winter time for the reduction of the temperature of antifreeze entering the object to the refrigerated cold frosty air is used with the refrigeration machine being turned off.

12-14

12-14

Application of a regenerative heat exchanger in the refrigeration cycle

Abstract

Аn efficiency of use of the regenerative heat exchanger in one-stage cycle with heat regeneration for different refrigerants has been considered. It has been shown that the use of a regenerative heat exchanger provides protection of the compressor from wet stroke and results in improvement of a number characteristics of refrigerating cycle efficiency.

16-18

16-18

Thermoelectric systems for thermal stabilization of small-sized radioelectronic equipment

Abstract

Designs of the devices for cooling and thermal stabilization of elements of small dimensions for radio electronics equipment are considered. The advantages and disadvantages of different types of devices are described, and their fields of application are indicated.

19-20

19-20

Flow-through steam milk cooler with a capacity of 250 l/h

Abstract

One way to increase the duration of the bactericidal phase of freshly milked milk is to cool it quickly. At the same time, the relatively low average logarithmic temperature head between the temperature of fresh milk and the temperature of the coolant used (in most cases it is water) necessitates the use of highly efficient flow-through coolers capable of functioning reliably under summer dairy farm operating conditions.

22-22

22-22

Maneurop compressors and units. News. Service features (Danfoss)

Abstract

Over the years, Danfoss has undergone significant changes, both in terms of improved equipment and customer service. Maneurop has been manufacturing compressors for 31 years. During this time the company has managed to attract millions of customers thanks to modern equipment based on advanced knowledge-intensive technologies. The merger of Danfoss with Maneurop has taken a new step in the development of compressor technology, making it possible to open a laboratory research and development center dedicated to bringing all the latest technologies to life.

24-25

24-25

Spiral fast freezers (Aircool)

Abstract

Aircool is one of the first Russian refrigeration companies, which started to supply and install equipment designed for the production of frozen products.

In order to ensure the best commercial appearance of frozen products it is necessary to maintain the low temperature required by technological standards in the freezing chamber. In this case, the capacity of the refrigeration unit and, accordingly, the consumed power is used only for the "pure" mass of the product.

26-27

26-27

AO Kholodmash: refrigeration compressors and units

Abstract

The main products of Kholodmash AO are refrigeration compressors of small cooling capacity (up to 3 kW) and compressor-condensing units designed for commercial refrigeration equipment. In recent years, the plant has mastered mass production of P series compressors manufactured according to Electrolux Compressors technology.

29-31

29-31

47-47

47-47